ALT F50 Curtain wall system

Due to its unique appearance and excellent performance characteristics, translucent facades gained popularity among architects and civil engineers. A building façade arranged of glass and aluminum framework can be of different color, properties, shape (vertical, tilted, horizontal) and etc. The structural glazing technique provides new design opportunities for building facades. The structural glazing systems conceal aluminum fastenings, hence the building face turns into a glass monolith. The Alutech Group offers facade systems for different types of structures, production and installation

|

|

|

| Download booklet | Download technical catalog | Download technical catalog |

ALT F50 post-transom facade

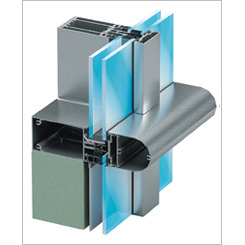

ALUTECH ALT F50 classic post-transom facade includes post and transom with 50 mm visible width. It enables maximum translucency and visual lightness of facade constructions, as well as a stylish apearance. All visible construction components can be painted with any RAL color. The quality of profiles coating confirmed by Qualicoat 2000. The most demanding customers are offered anodized profiles resistant to aggressive exposure of the environment. The set of available thermal inserts and gaskets provides the installation of fillings (glass units, thermal insulation panels) from 4 to 50 mm thick.

Advantages

Primary distinguishing advantages of the system are as follows.

-

High degree of thermal insulation (Group 1.0).

Today, when prices for all types of energy resources are constantly rising, it is impossible to stay clear of problems related to environment and resource saving to create comfortable climate in a facility. To ensure good thermophysical and sound insulation of a building envelope, the ALUTECH ALT F50 series uses a set of thermal inserts (thermal insulators) made of hard impact-resistant polyvinyl chloride (PVC-U-HI) with high heat insulation parameters, co-extrusion sealant (patented solution) and a number of sealing gaskets based on ethylene-propylene rubber (EPDM). Due to optimal combination of these components the following thermal insulation parameters are provided (according to DIN 4108-4):standard solution includes heat transfer rate of Uf = 2.4 W/(m2K) or reduced total thermal resistance Rred.= 0.42 m2°C/W (frame materials group 2.1).

This provides for significant improvement of thermophysical characteristics without dramatic increase in the value of 1m2 of the construction.

-

«Warm-Cold» system.

Using original PVC separators in party walls and crossings of the facade makes it possible to use single-thickness sheet glass rather than a glass unit. Availability of special grooves enables covering thermal insulation with any inexpensive panel material. It ensures economy transfer from nontransparent to transparent area of the structure without deprivation of thermal insulation properties. Taking into account the fact that for the last two years the market price for plate glass has increased by several times, such object solution is increasingly used by developing surface-mounted translucent facades.

-

Multiple connection options for basic profiles and simplicity of processing.

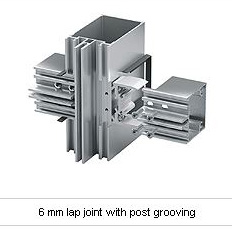

The facade series ALUTECH ALT F50 provides for several types of connecting post to transom:

- end joint (without profiles milling using slotted jet nut element);

- 6 mm lap joint (without post grooving);

- 6 mm lap milling (with post grooving).

General description of the system

F50 system enables start of aluminum structures production at minimum time and costs, while companies already working with aluminum profiles can quickly switch to ALUTECH ALT F50 without changing basic types of connecting and machining post and transom.

Besides, there are several means of connecting post and transom:

- using chamber jetnut elements (step-by-step installation);

- using chamber jetnut elements and slides (simplified installation);

- using butt transom self-tapping screws (simple and economy-type connection with preliminary machining of the post).

Several connection variants for the profiles give manufacturers with different experience and different equipment an opportunity to work with the system, and to apply in each specific case the most appropriate and technologically advanced means of connection in facilities of various classes.

-

Interchangeability of main profiles

All posts and transom profiles have grooves in the filling install area that serve to remove condensate and ensure ventilation of the glass unit lock seam area. Section configuration of all posts and transoms makes it possible to use the profiles as both vertical and horizontal profiles of the facade frame.

During manufacture of facade constructions the processing companies often have 0.5-2-meter residues of post profiles that cannot be used anywhere due to their small length. Application of a post as a transom reduces waste of post profiles and optimizes pattern cutting of the shapes during the engineering of facade constructions. Thus the reduction in the number of used standard profiles allows the reduction of the end construction cost.

For constructions that do not need to have high rigidity ALUTECH ALT F50 system provides an opportunity to use transom profiles as vertical bearing profiles. To ensure vertical detachment (of reinforcement) of transom chamber rack-type reinforcing profiles are used. It significantly reduces metal consumption, which means the reduction of the end construction cost.

Also, the configuration of main profiles makes it possible to abandon the use of second level transom, thus reducing the stock-list of the profiles. Instead of the second level transom it is recommended to install standard post or transom profiles.

-

Variety of construction solutions.

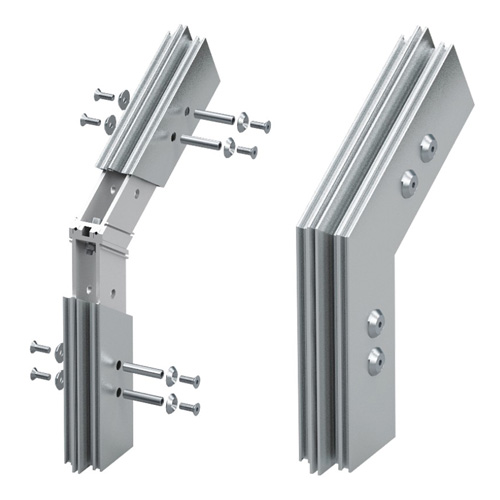

A unique structure of jetnut profiles (patented solution) enables various bridges and variants of joining facade constructions with building components:

- Creation of kinked surfaces — vertical tilted posts (transition from vertical to tilting part of the construction);

- The post can be rotated in the stained glass window pane;

- Creation of tilt-rotary surfaces;

- Adjoining of tilted construction to the building foundation;

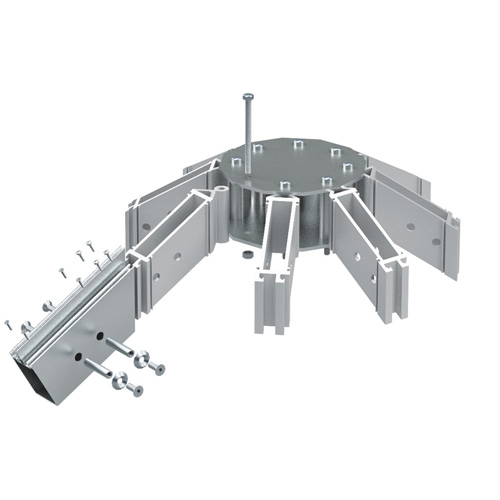

- Creation of multifacet pyramid vertex.

-

Stock of required single-piece component parts.

It is not a secret that all post-transom systems are very much similar to each other. Unfortunately, the majority of domestic systems lack the sufficient number of component parts that play an important part in faultless functioning of facade constructions and are an additional decorative element. ALUTECH ALT F50 system includes the required suite of such items that provide:

- decoration of post-transom joint area, as well as vertical junction of two posts;

- the required air circulation and moisture removal from the glass unit lock seam area;

- removal of water and other atmospheric precipitations from the outside surface of the glass unit in tilted structures;

- simplification of post-transom connection.

Semi-Structural Glazing ALT F50 HL

.jpg) Besides, instead of standard clamping and decorative plates with visible width equaling to 50 mm, this system allows using clamping profiles F50.1601 or F50.1602 with visible width 38 mm. This being the case of another modification of post-transom system - ALTF38 HL “Horizontal Line 38 mm”.ALT F50 HL “Horizontal Line” system is still another variety of post-transom facade ALTF50, where one of directions of the glass unit clamp is distinguished from outside – horizontal or vertical. This is achieved by applying of various camouflaging plates (e.g., elliptical F50.0507 or semi-circular F50.0505) highlighting one direction, thus providing the building with some additional volume, either horizontal or vertical. Moreover, for lines going in the other direction, glass unit fixing profiles are replaced with a decorative joint gasket, or the space between glass units is filled with joint silicone sealant resistant to various weather exposures.

Besides, instead of standard clamping and decorative plates with visible width equaling to 50 mm, this system allows using clamping profiles F50.1601 or F50.1602 with visible width 38 mm. This being the case of another modification of post-transom system - ALTF38 HL “Horizontal Line 38 mm”.ALT F50 HL “Horizontal Line” system is still another variety of post-transom facade ALTF50, where one of directions of the glass unit clamp is distinguished from outside – horizontal or vertical. This is achieved by applying of various camouflaging plates (e.g., elliptical F50.0507 or semi-circular F50.0505) highlighting one direction, thus providing the building with some additional volume, either horizontal or vertical. Moreover, for lines going in the other direction, glass unit fixing profiles are replaced with a decorative joint gasket, or the space between glass units is filled with joint silicone sealant resistant to various weather exposures.

Like in other versions of ALTF50 facade, constructions of “Horizontal Line” type can use hinged windows of “concealed leaf” type without altering the facade appearance.

Use of available thermal inserts and gaskets allows installation of glass units 22 - 38 mm thick manufactured in compliance with requirements imposed for structural glazing. Glazing, as well as installation of window blocks, is done form outside of the building.

ALT F50 HL has several principle advantages in comparison with similar systems available on the market:

- Vertical space between glass units in ALT F50 HL system may be filled with a special gasket installed into thermal bridge groove, instead of joint structural silicone.

- In horizontal direction a clamping plate with decorative cap from the standard post-transom system is applied (with visible width 50 mm), or clamping plate form ALT F50 SSG (with visible width 38 mm).

Semi-structural glazing ALT F50 SSG

.jpg) Primary difference of this facade solution is the absence of wide 50-mm clamping and decorative caps. In their stead narrow clamping profiles are used, which almost invisible from outside, simulating the structural joint.ALT F50 SSG modification is designed for semi-structural glazing of building facades. The solution has been developed on the basis of classic ALT F50 post-transom series. Standard posts and transoms of the system with 50 mm visible width are used as the bearing structure.

Primary difference of this facade solution is the absence of wide 50-mm clamping and decorative caps. In their stead narrow clamping profiles are used, which almost invisible from outside, simulating the structural joint.ALT F50 SSG modification is designed for semi-structural glazing of building facades. The solution has been developed on the basis of classic ALT F50 post-transom series. Standard posts and transoms of the system with 50 mm visible width are used as the bearing structure.

In this system integrated semi-structural windows can be built-in into the facade structure as window blocks.

Use of available thermal inserts and gaskets allows installation of glass units 28 - 50 mm thick manufactured in compliance with requirements imposed on structural glazing. Glazing, as well as installation of window blocks is done form outside of the building.

Primary advantage of ALT F50 SSG is the facilitation of integrated windows installation into the semi-structural facade:

- There is no cutting and joining of clamping plate up to 45º. In similar systems an asymmetrical clamping plate is applied across the entire window perimeter; to provide formal resemblance across the entire facade it shall be cut at 45º. In ALT F50 SSG system in all facade areas a symmetrical clamping plate is applied, so there is no necessity to use a clamping plate of another type and cut it at a certain angle.

- The window is delivered to the site completely assembled, so installation (and adjustment) of the furniture at the site is not required. In similar systems installation and subsequent adjustment of the furniture is carried out during the installation, not in the shop. Since many installers do not have sufficient qualification and experience in structure assembly, there are good chances that some error will be made during the installation works. Due to the absence of an adequate frame structure, during the installation of semi-structural facades it was necessary to install the counter part of the furniture on the post (or transom). In ALT F50 SSG system window structures a frame profile is used that provides the assembly of the window block in the shop and send it to the site ready-to-use. Thus the installers do not have to perform works related to the installation and adjustment of furniture, which is unfamiliar to themю

- Two types of clamping profiles and decorative element.

SG structural glazing

The offered system of structural glazing is designed for manufacture of translucent facades without visible fastening of glass units. The filling is fixed from the filling end, the space between glass units is fitted with thermal insulation materials, from the outside the joint is made off with silicone sealant or gasket. This system is based on ALT F50 transom-post facade system.

To produce facades with structural glazing it is necessary to use special glass units that includes U-profiles with attached double stick tape AYPC.F50.1702 and secondary structural silicone sealant (e.g., Dow Corning 3362 and 3793, Sika IG-16 и IG-25). The adhesive surface of AYPC.F50.1702 profile allows its fast and easy installation across the entire perimeter of inner glass, then the space between the glass at the glass unit's end is filled with secondary sealant. ALT F50 SG system provides for the application of a wide range of glass: inner glass 6, 8, 12 and 14 mm thick, outer glass 6-12 mm glass, which eventually makes it possible to create facades with glass units of large area.

After installation of the post-transom framework, the glazing of the facade starts. Prior to installation of glass units, clamping elements are installed into the U-profiles grooves. Then the filling is installed on support plates, and end clamps are fixed in the central groove of the pos and transom using trim-head screws Ø 5.5 DIN 7982. Based on the results of tests the maximum tear-out bearing capacity of attaching point consisting of a clamp and two screws exceeds 1000 N. Across the entire perimeter of the glass unit there are more than 10 of such points. This ensures safe fixation of the filling in the structure and exclude its accidental falling out.

At subsequent stages thermal insulation materials are installed into the glass unit lock seam area and the decorative make off of the joint takes place. Well known clamping bars and covers of classic post-transom system are replaced with decorative joint sealant (FRK47 and FRK48), or with silicone sealant (e.g., Dow Corning 797 or Sikasil WS-304) resistant to different weather exposures.

To provide "conditionally cold" areas a combination of aluminum and PVC profiles is provided in the system. The Aluminum profile serves as a guide for the clamping element, the PVC profiles is designed to reduce heat losses, align gap between the glass and aluminum frame, and, as required, to install a sheet material panel behind the glass. The PVC profiles is attached to the aluminum frame assembled with angular embedded components.

This frame structure is attached to glass using silicone sealant (e.g., Dow Corning 995 and 895 or Sikasil IG-18 and IG-20). The resulting glazed unit, just like a glass unit, is fixed with the help of clamping elements.

If appropriate, sheets made of composite materials, aluminum or stainless steel may be used as a filler in impervious area. In this case the materials are attached using double stick tape 3M G23F and B23F.

To provide safety ALT F50 SG system has securing components AYPC.F50.1946 and AYPC.F50.1948 that ensure mechanical support of the outer glass and prevent the filler from falling out in case of earthquakes, hurricanes and other force-majeure circumstances.

To produce jut facades and various angular transitions, ALT F50 SG system uses angular clamping elements, that enables rotation of the space frame on one post at any angle from -90º to +90º.

ALTF50 integrated window construction is offered as an opening component in structural facades, which proved itself as one of the best solutions for post-transom systems. The appearance of such a window in closed position is practically indistinguishable from blind parts of stained glass, thus providing a uniform "glassy" layout of the entire structural facade, free from clamps and decorative covers.

ALT F50 SG structural glazing system has a number of competitive advantages:

- Manufacture of constructions of various configurations and degree of complexity (straight, angular, jut, tilted).

- Wide range of fillers: glass units from 26 to 40 mm with glass 6-14 mm thick, or single-piece glass and sheet materials for impervious areas.

- Simplified manufacture of glass units: preliminary attachment of U-profile to the inner glass significantly reduces the assembly time of structural glass units.

- Easy installation of glass units: preliminary installation of clamps into U-profile groove facilitates the installation of the glass unit into the facade frame.

- Installation of super-heavy fillers: swiveling combination of bottom plates for heavy glass units enables installation of large-size filler up to 400 kg with glass up to 14 mm thick.

- Two variants of joints make off between glass units: silicone sealant or gaskets FRK47 and FRK48.

- Two variant of glass units fixing in "concealed sash": attaching on silicone sealant or using a set of gaskets and skirting profile.

- Good thermotechnical properties: with filler 26 mm thick, the heat conductivity of integrated window standard section is 2.7 W/m2*ºK; for structural glazing this value is 1.4 W/m2*ºK.

- Assembly using swiveling embedded trapezoid (triangular) frames and installation of non-rectangular single-piece fillers into impervious areas of facade.

- Development of subobject solutions: application of two-chamber glass units in structural glazing, capability to install fillers up to 52 mm thick and etc.