ALT IGF65 Stained glass system with thermal insulation

Stained glass system with thermal insulation ALT IGF65 is designed for the manufacture of translucent stained glass structures. A distinctive feature of the system is the ability to make installation from inside the room without the use of scaffolding and cradles.

Assembling of structures at the facility can be done either as ready sections, or as separate elements.

Assembling of structures at the facility can be done either as ready sections, or as separate elements.

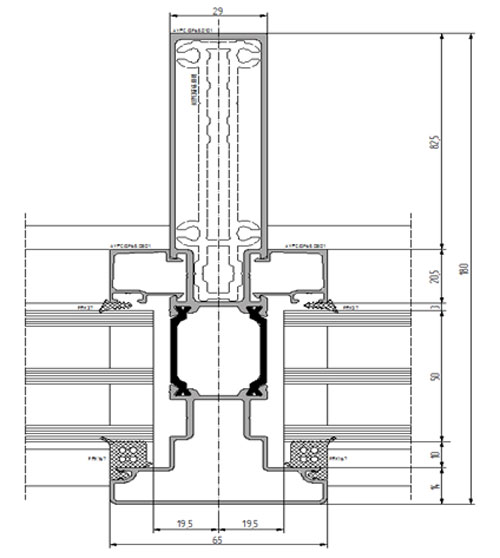

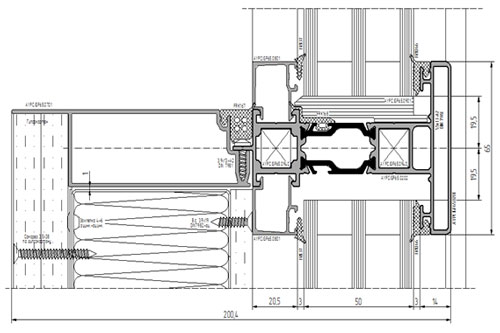

The basis of the ALT IGF65 system is based on supporting combined profiles of posts and girders, which are interconnected by means of rusks.

The range of the system includes aluminum profiles of its own production (including combined ones), EPDM-based rubber seals, foam polymers seals, plastic caps, aluminum profiles parts, as well as fasteners and auxiliary products.

The range of the system includes aluminum profiles of its own production (including combined ones), EPDM-based rubber seals, foam polymers seals, plastic caps, aluminum profiles parts, as well as fasteners and auxiliary products.

Characteristics of the ALT IGF65 system:

- installation of facades made from the inside (for installation does not require scaffolding, which guarantees the safety of the work);

- the possibility of sequential and parallel-sequential installation of the post-bolt frame;

- installation and replacement of fillings both from the inside and the outside;

- ease of processing the rack and bolt (in the presence of a pneumatic press);

- ease of attachment;

- the presence of a full fire cutoff;

- high thermal performance;

- high thermal performance of the pitch;

- improved air permeability and sound insulation of the facade through the use of additional sealing elements and inserts around the perimeter of the glass.

Technical documentation

Feasibility study for stained glass system ALT IGF65

Download

Скачать

Technical catalog

Stained glass system with thermal insulation ALT IGF65

The stained glass glazing system with thermal insulation ALT IGF65 is designed for the manufacture of translucent stained glass structures. A distinctive feature of the system is the ability to carry out installation from inside the room without scaffolding and cradles. Assembling at the facility can be done both with prefabricated sections, and with separate structural elements.

The system is based on supporting combined profiles of struts and girders, which are interconnected by means of rusks. The system includes aluminum profiles of its own production (including combined ones), EPDM-based rubber seals, foamed polymer seals, plastic plugs, aluminum profile parts, as well as fixing and auxiliary products.

Download

Скачать

- Installation and the ability to replace glass in the area of interfloor overlaps without the use in the construction of prefabricated racks;

- Installation of integrated windows by opening out (possibly due to a developed internal profile cup, with a pylon outside there is no such possibility);

- Installation of fireproof cut-offs of full factory readiness;

- Tightness of the junction of racks vertically without damage to thermal compensation;

- The sealing groove of the beadings allows the use of additional profiles and seals of the facade system AYPC.F50;

- The ability to carry out installation from the inside, even on the wall space (provided that the walls will be laid out after the installation of IGF65 structures);

- Thanks to the use of the strut-bolt joint caps made of foamed EPDM and the FRK168 seal, high rates of air and water tightness of the structures are achieved;

- The ability to manufacture structures of both mounted and built-in types.

ALT IGF65 Scope:

- the vertical structures of the stained-glass windows are straight and turning in plan (standard angles of ± 90 °, arbitrary angles, radius structures with a fixed kink angle throughout the entire object);

- maximum pitch racks 1,5m;

- height of span 2.8 - 3.3 m;

- maximum filling weight 150kg;

- maximum section weight 350kg;

- thickness range of fillings 4 - 50mm;

- integrity and heat insulating ability of EI60 for a fire cut-off (at least 60 minutes);

- reduced resistance to heat transfer design

- Rpriv.1> 1 (m2 * ° С) / W, Rpriv.2> 0.6 (m2 * ° С) / W (when using 24mm thermal bridges).

Heat engineering, water penetration, air permeation

At the Research Institute of the Republic of Belarus (BelNIIS) field tests of the construction of a stained glass system with thermal insulation ALT IGF65 were successfully carried out, confirming that the heat transfer resistance coefficient Rpriv = 1.21 (m2 * C) / W and 1.24 ( m2 * C) / W. This suggests that at the moment the system IGF65 - is a system of all the profile systems offered by the ALYuTEH Group of Companies. In terms of water and air permeability, the experienced design of the ALT IGF65 system also showed the highest result, namely class A.